Search Results

Filter Your Search

Category Group

Category Group

Shop by Category

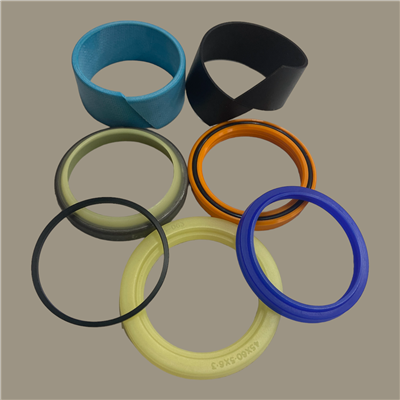

O-rings as elastic loops that seal static and dynamic applications. They are used to seal the space between cylinders, pistons, pipes and tubes and can be made from various materials.

70 Durometer | Buna-N Rubber Material | 1 7/8 in Nominal Inner Diameter | 1/16 in Cross Section | O-Ring

Features

- Pressure range varies according to diametral clearance

- Temperature range of -40 °F to -240 °F

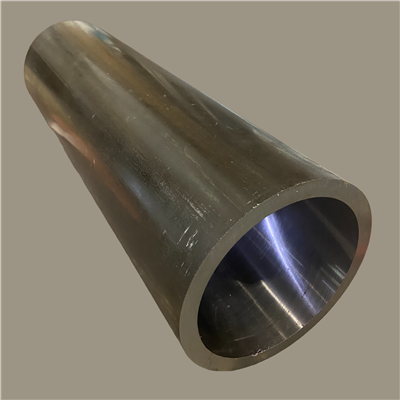

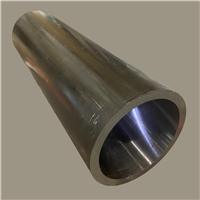

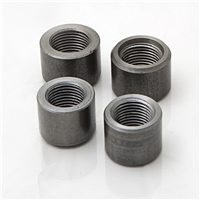

HT-6500X5500 has a wall thickness of 0.5 in. The ID is 5.5 in and the OD is 6.5 in. The material is DOM 1026 Carbon Steel and has been stress-relieved and annealed.

Full mill lengths will be cut to lengths between 12 ft and 19 ft long. Packages longer than 44 inches may have additional freight charges.

| 1-14 | $16.42 |

| 15-59 | $14.35 |

| 60-104 | $12.74 |

| 105+ | $11.48 |

The PS1800 provides low friction, high strength piston sealing. The PS1800 also provides double-acting piston sealing in a compact design that meets the requirements of ANSI/B93-32-1973. Piston diameter “I” dimensions are given for pistons without wear rings.

15% Glass Filled PTFE Material | 2 11/16 in Nominal Inner Diameter | Piston Seal

Features

- Easy assembly

- Low friction capabilities

Style 850 u-seals offer excellent resistance to extrusion and abrasion. The round cross-section expander offers energized sealing from zero to 5,000 psi.

95A Durometer | Urethane Material | 3 1/2 in Nominal Inner Diameter | 7/32 in Cross Section | U-Seal

Parback® backup ring with a curved cross-section.

Parbaks are contoured on one face to minimize distortion of the o-ring when under pressure. Parbaks should be installed with the contoured face against the o-ring, but reversal does no harm.

90A Durometer | Buna-N Rubber Material | 1 13/16 in Nominal Inner Diameter | 3/32 in Cross Section | Backup Ring

Features

- Excellent extrusion resistance

- Easily stretched for installation

- Lubrication is enhanced by rubber which absorbs system fluid and does not plate out on rubbing surfaces

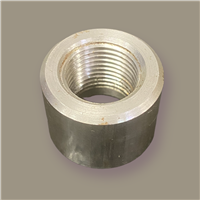

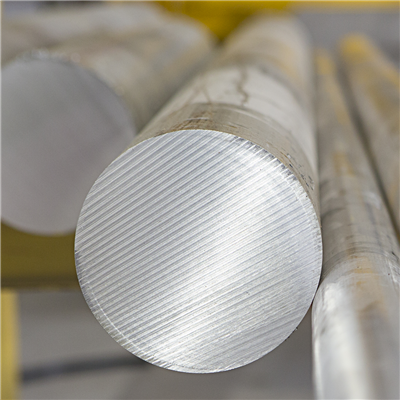

ALUM-2500 has a 2.5 in diameter. The material is 6061 Aluminum T6

6061 Aluminum T6 is suitable for machining pistons and head glands.

The T6 refers to the temper or degree of hardness. T6 has been solution heat treated and artificially aged to provide the maximum yield strength for a 6061 aluminum alloy.

- Heat treated and aged for increased strength

- Easily formed

- Weldable

- Corrosion resistant

Full mill lengths will be cut to lengths between 12 ft and 19 ft long. Packages longer than 44 inches may have additional freight charges.

| 1-14 | $6.08 |

| 15-29 | $4.35 |

| 30+ | $3.37 |