Search Results

Filter Your Search

Category Group

Category Group

Shop by Category

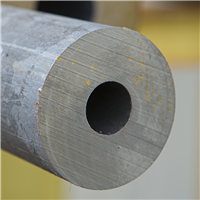

HWT-3000X1000 has a wall thickness of 1 in. The ID is 1 in and the OD is 3 in. The material is 1026 Carbon Steel.

Heavy Wall Tubes are used for machining high strength and close tolerance parts like bushings, axles, hydraulics, and sleeves.

Full mill lengths will be cut to lengths between 12 ft and 19 ft long. Packages longer than 44 inches may have additional freight charges.

| 1-4 | $6.32 |

| 5-24 | $5.53 |

| 25-49 | $4.91 |

| 50+ | $4.42 |

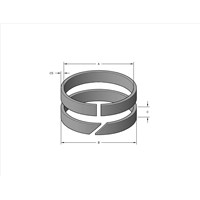

Totally interchangeable with Style PS1400 PTFE piston seals, Style PS1500 piston seals are molded from tough 60 Shore D durometer polyurethane. During the molding process, a .002” thick band of molybdenum disulfide is molded into the outside diameter of the seal ring for reduced friction. PS1500 piston seals are easily stretched over the piston and recover rapidly with the elimination of the “cold flow” characteristics found in PTFE seals. Piston diameter “I” dimensions are given for pistons without wear rings.

60 Shore D Durometer | Polyurethane Material | 1.606 in Nominal Inner Diameter | Piston Seal

Features

- Easy assembly

- Low friction capabilities

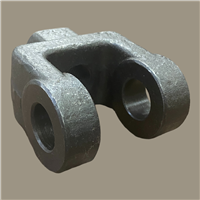

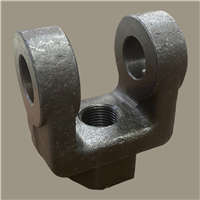

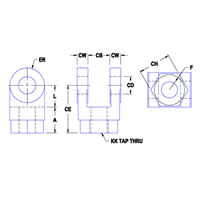

Steel Rod Clevis Mount with a 0.75 in – 16 TPI threaded end and a 0.75 in pin hole.

Clevis mounts help maintain alignment and protect the cylinder from side load. Mounts attach to threaded stud ends, pivot holes, or bolt holes on the cylinder. Can be used with hydraulic cylinders with standard bore sizes.

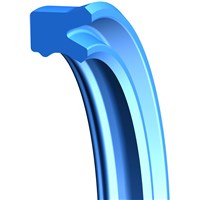

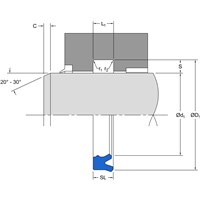

Asymmetric rod seal designed with precision trimmed sealing lips to provide a dry sealing solution in light and medium-duty applications. The Hallite 605 is molded in Hythane® 181, Hallite’s high-performance polyurethane, for easy installation and excellent low temperature performance. The twin lip design helps solve difficult rod sealing problems by providing lower friction, increased stability, and high, dynamic lip force, while preventing air penetration from outside the cylinder. Designed to have interference in the seal housing groove and has a secondary lip. The secondary sealing lip located behind the primary sealing lip improves stability of the seal in the gland. The inner dynamic lip is shorter and more robust to improve sealing and compression set characteristics over conventional, symmetrical U-seals.

The seal can be considered for use in heavy-duty applications when used with a suitable full depth back-up ring. The sealing lips are precision trimmed at an angle to give optimal rod sealing performance.

94A Durometer | Urethane Material | 2 in Nominal Inner Diameter | 3/16 in Cross Section | U-Seal

Features

- General purpose rod seal

- Robust design

- Excellent wear resistance

- Increase seal stability

- Performs well over wide temperature range and is extremely effective in low temperatures

- Primary lip protection

- Easy to install

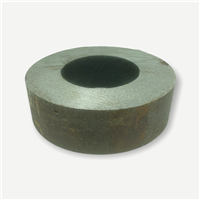

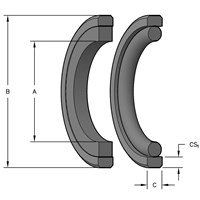

Molded from filled PTFE and machined to close tolerances, these seals feature low friction and excellent wear characteristics. Nitrile rings are used for energizers.

70A Durometer | PTFE Material | 52 MM Nominal Inner Diameter | Piston Seal

Features

- Easy assembly

- Low friction capabilities

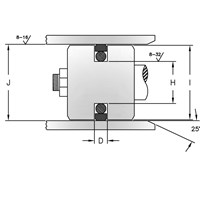

Molded in urethane, this wiper features a double lip which prevents fluid that seeps by the rod seal from exiting the cylinder.

Urethane Material | 35 MM Inner Diameter | Wiper

Suffix “V” designates fluorocarbon material,“N” designates nitrile material, and “HT” designates high temperature urethane.

90A Durometer | Urethane Material | 4 in Nominal Inner Diameter

Features

- Urethane Wiper Ring

- Min. Temperature Range of ‘-40 °F; N: -40°; V: -20 °F; HT: -40 °F

- Max. Temperature Range of 200 °F; N: 225 °F; V: 350 °F; HT: 225 °F

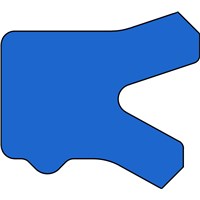

This wear ring is molded from glass reinforced nylon. This style is highly recommended because of their wear rate and non-scoring properties and their ability to ingest metal chips.

Nylon Material | 45 MM Nominal Inner Diameter | Wear Ring

Features

- Protection Against Wear

- Reduced Friction

- Extended Cylinder Life

- Operational Efficiency

O-rings as elastic loops that seal static and dynamic applications. They are used to seal the space between cylinders, pistons, pipes and tubes and can be made from various materials.

70 Durometer | Buna-N Rubber Material | 3 1/4 in Nominal Inner Diameter | 3/32 in Cross Section | O-Ring

Features

- Pressure range varies according to diametral clearance

- Temperature range of -40 °F to -240 °F

The PS1400 seals offer low friction and high strength in a compact double-acting piston seal design. The PTFE seal ring, combined with a rubber energizer, assures positive contact with the dynamic surface. The PS1400 is designed to fit ANSI/B93.32-1973 groove standards. Piston diameter “I” dimensions are given for pistons without wear rings.

15% Glass Filled PTFE Material | 3.108 in Nominal Inner Diameter | Piston Seal

Features

- Easy assembly

- Low friction capabilities